How is frosted glass made? 4 techniques explored

Share this blog:

Frosted glass provides privacy and aesthetic appeal. Explore the different ways it's made in our guide.

Frosted glass is a staple in homes and offices across the UK and beyond.

Like many glass products, it's popular because it does two things at once – one functional, the other aesthetic.

Frosted glass provides privacy, whether in the bathroom or the boardroom, with opacity levels ranging from 10% to 100%. At the same time, it has a beautiful texture, light-diffusing properties and practically endless design potential.

Not all frosted glass is made in the same way, however. There are two main manufacturing methods: acid etching and sandblasting. Acid etching gives the glass a soft, cloudy finish while sandblasting gives it a rougher surface.

Glass can also be frosted at home. While the results can be convincing, they're unlikely to be as good as their professionally produced counterparts.

At ToughGlaze, we provide clients in a range of sectors with high-quality sandblasted glass. Want to find out more about this most versatile of products? Here we go.

Applications of frosted glass

There are two main applications of frosted glass: privacy and decoration.

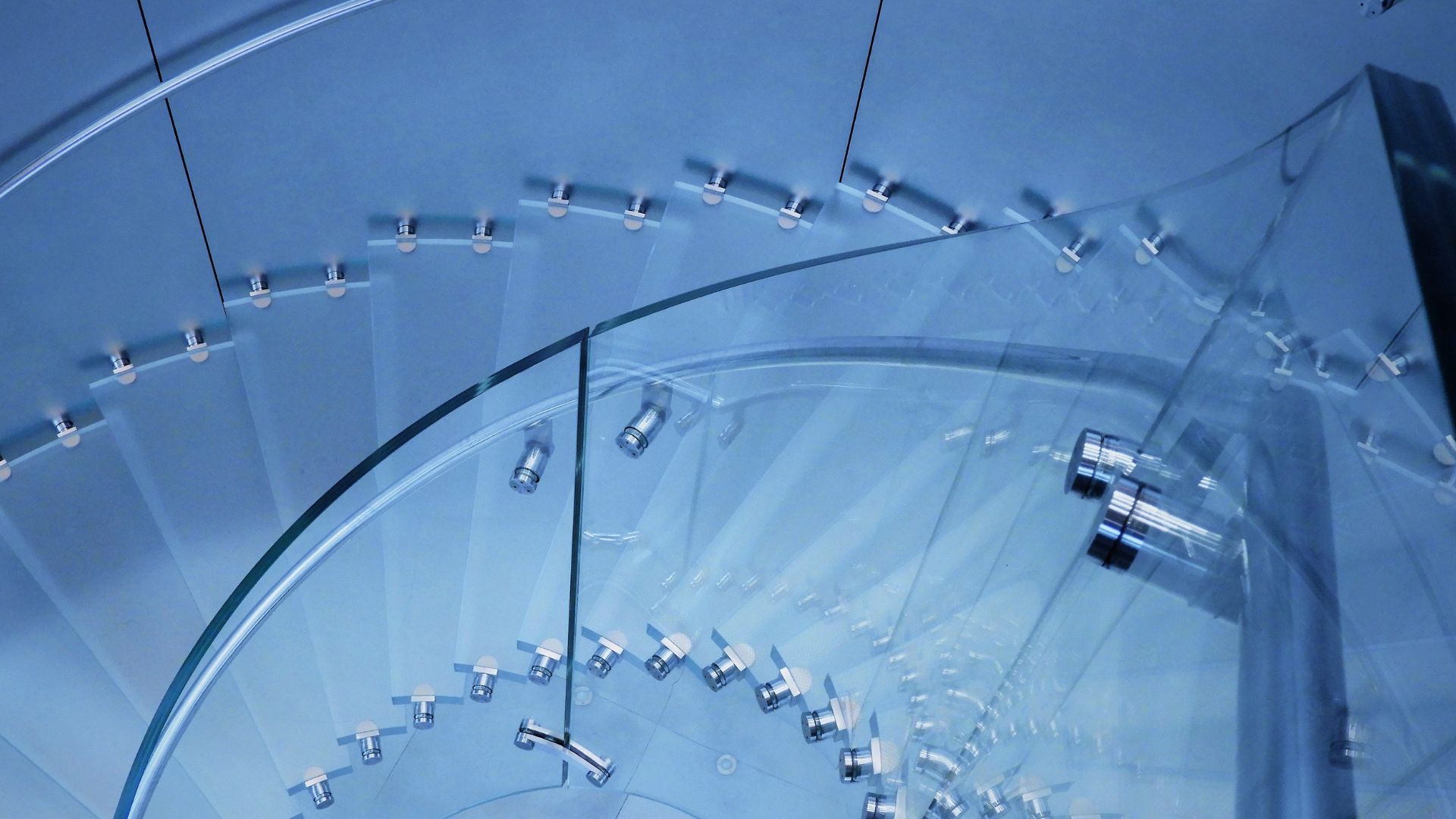

In domestic and commercial settings, frosted glass provides privacy in bathrooms and shower units. And in offices and other workplaces, it can be used for office partitions and conference rooms.

But frosted glass isn't purely functional. It has a lot of aesthetic potential. This ranges from simple patterns like dots and lines to intricate designs.

Shelves and kitchen splashbacks can be decoratively frosted. Artists use it to explore gritty and cloudy textures. And businesses can consolidate their branding using carefully presented logos and other brand elements.

Frosted glass can also make a room feel softer and more welcoming. It does this by refracting the light around the room. On a sunny day, the room is filled with gently diffused light rather than a blast of solar glare. For many, this is a superior option to a curtain, blind or drape.

How is glass frosted?

1. Acid etching

Acid etching is one of the most common industrial methods for frosting glass. It involves applying a strong acid solution to the glass and etching away a thin layer. Typically, hydrofluoric acid is used.

Etching gives the glass a smooth and uniform finish. It's variously described as soft, cloudy and milky. This distinguishes it from sandblasted glass, which has a grittier texture.

Like sandblasting, acid etching can be applied to an entire pane of glass or to selected parts, creating intricate patterns. The opacity can be controlled. Most acid-etched glass has an opacity between 10% and 20%. However, it can go up to 100%.

2. Sandblasting

Here at ToughGlaze, we specialise in glass sandblasting. Whereas acid etching involves the application of hydrofluoric acid, sandblasting involves blasting a pane of glass with a high-pressure abrasive substance. This is typically sand but can also include crushed-up walnut husks and other materials.

The result is a rougher, more textured effect than acid-etched glass – but no less beautiful. Its combination of privacy and beauty makes it ideal for homes and offices alike.

Like acid-etched glass, sandblasted glass can have a range of opacities. This is controlled by the speed and pressure of the sand flying out of the sandblasting machine.

And like acid-etched glass, the frosted effect can be applied to a whole pane of glass or stencilled on to create designs. These can be dots, lines or logos.

Sandblasted glass differs from acid-etched glass in one important way. The use of chemical etchants in acid-etched glass means you can't recycle it easily. Sandblasted glass, however, can be recycled – a plus for any company with sustainability in mind.

To learn more about the versatile applications of sandblasted glass, check out our guide to visual effects with sandblasted glass.

3. Frosted window films

Acid-etched glass and sandblasted glass both need to be installed. But what if you want to add a frosted glass effect to an existing window, partition or other glass feature?

This is where frosted window films can help. These are adhesive pieces of vinyl that provide a frosted effect.

Some frosted window films are better than others. And while they can have good results, be aware that they don't let in as much natural light as frosted glass products.

It's also worth considering that if you add a frosted window film to an old piece of glass, you're not getting all the benefits of high-quality modern glass.

4. DIY methods

It's possible to frost glass yourself – although not to the standard you can expect from an industrial glass processor.

Etching creams and frosted glass sprays are available. You can also apply a solution of water, Epsom salt and washing up liquid with a sponge, paint brush or spray bottle.

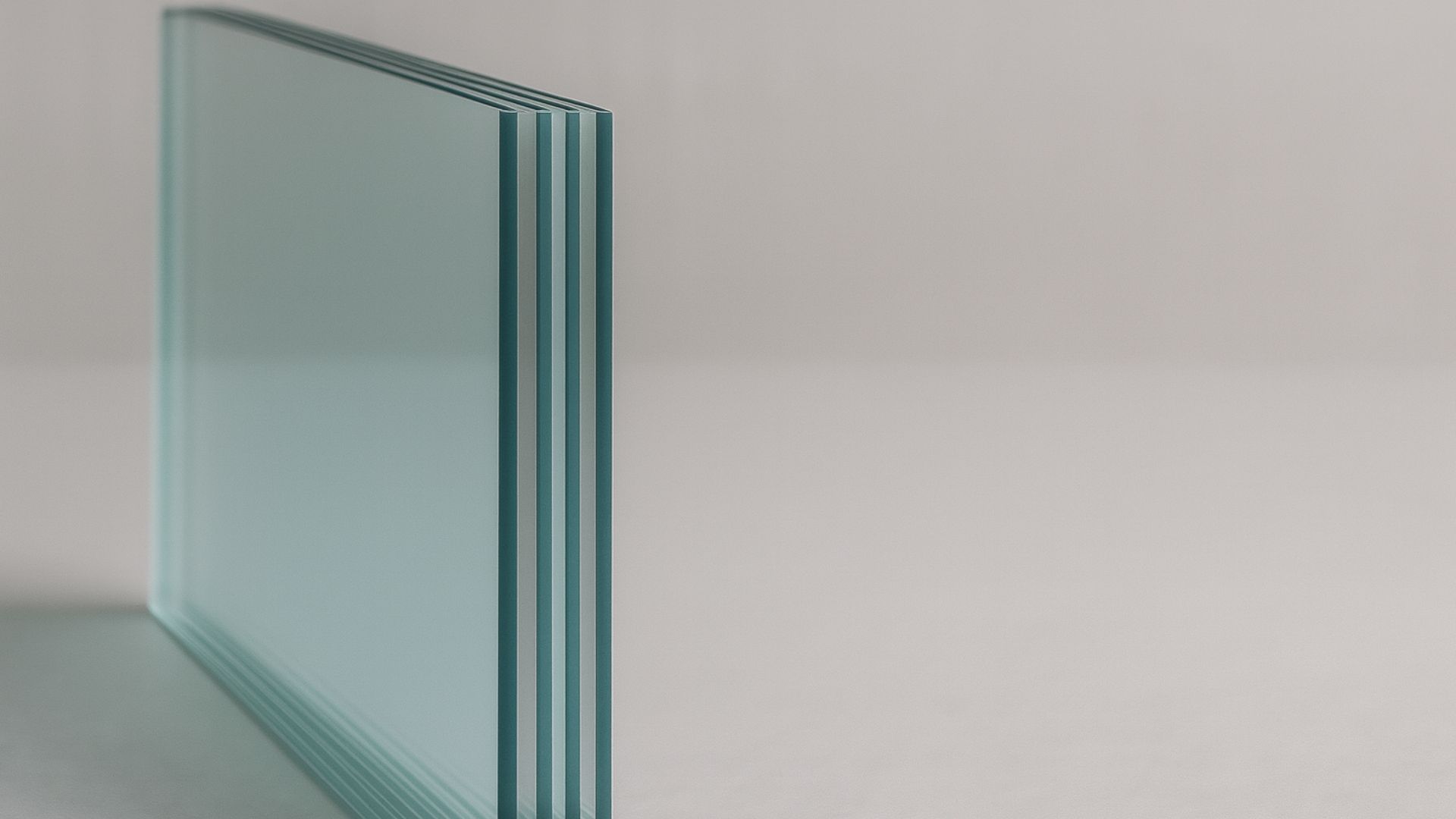

Toughened and laminated glass

Toughened and laminated glass are types of safety glass used in applications where extra safety is needed. And like standard annealed glass, they can be acid-etched or sandblasted with patterns, logos and more.

Frosted toughened or laminated glass is a great example of how glass can be both functional and beautiful. The glass provides durability, safety and privacy as well as an elegant, modern look.

Frequently asked questions

Can frosted glass be recycled?

Acid-etched glass can't be recycled because of the chemical etchants used in the manufacturing process. Sandblasted glass can be recycled so long as it's uncontaminated.

Can you see through sandblasted glass?

Sandblasted glass is translucent. While it can be fully opaque, it's usually manufactured to let in natural light.

How do you clean acid-etched glass?

As with many types of glass, gently does it. You want to use mild detergent and a soft sponge or cloth. The same goes for sandblasted glass.

Are you looking for glass sandblasting services? ToughGlaze is one of the UK's most trusted and recognised glass processors. Get in touch today for a quick, competitive quote.